MENU

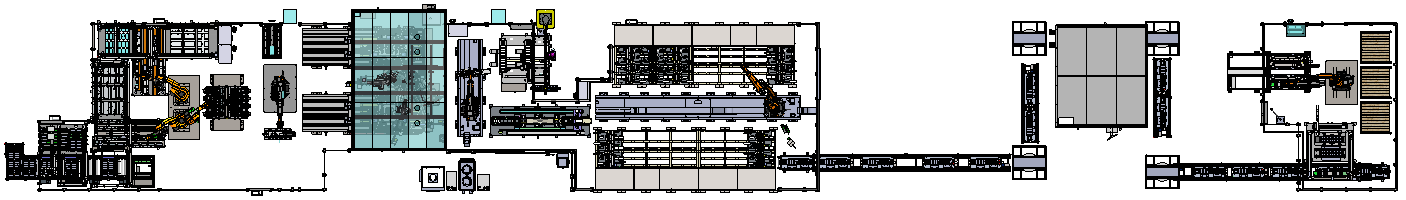

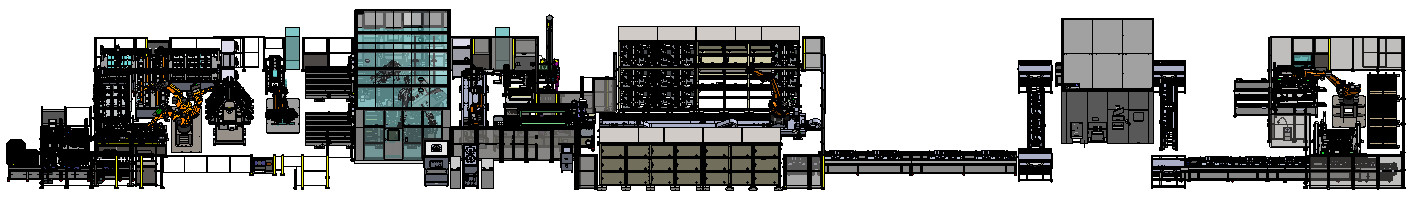

Basic process: including core loading, OCV test, core cleaning, module stacking, side plate gluing, side plate welding, weld cleaning, module size detection, module static, insulation test, Busbar welding, Busbar weld cleaning, EOL test, visual inspection

Basic process: including core loading, OCV test, core cleaning, module stacking, side plate gluing, side plate welding, weld cleaning, module size detection, module static, insulation test, Busbar welding, Busbar weld cleaning, EOL test, visual inspection

Technical highlights: flexible design, rapid compatibility and type change of different battery modules can be achieved through fine-tuning mechanism, fixture replacement and switching procedure. The number of cells is compatible with 4-16 cells, and the whole module line is compatible with the requirements of MEB series and VDA series products. The production line uses intelligent robots, flexible grippers, laser welding, two-component gluing, plasma cleaning, CCD intelligent detection and EOL testing technology, as well as powerful data management functions, real-time display of production information, real-time tracking and recording of product and equipment paraMeters.

Introduction to square shell equipment line

Introduction to thread body:

The whole line has the functions of automatic core on-line, core pretreatment, side plate and foam on-line, side plate gluing, core stacking, module and side plate welding, module transfer and cleaning, module static, module test, CCS installation, CCS welding, module secondary test, dimension detection, module weighing and off-line.

Line body equipment paraMeters:

Line body area: 60000 × 9600X2500(mm)

Energy consumption: 220KW/piece

Equipment capacity: 12PPM/piece

Crop rate: ≥ 98%

Equipment yield: ≥ 99%

Switchboard: 0512-62981499

Fax: 0512-62981525

E-mail: tech-shine@tech-shine.com.cn

Address: No. 938, Chengyang Road, Economic Development Zone,

Xiangcheng District, Suzhou, Jiangsu Province

Focusing