MENU

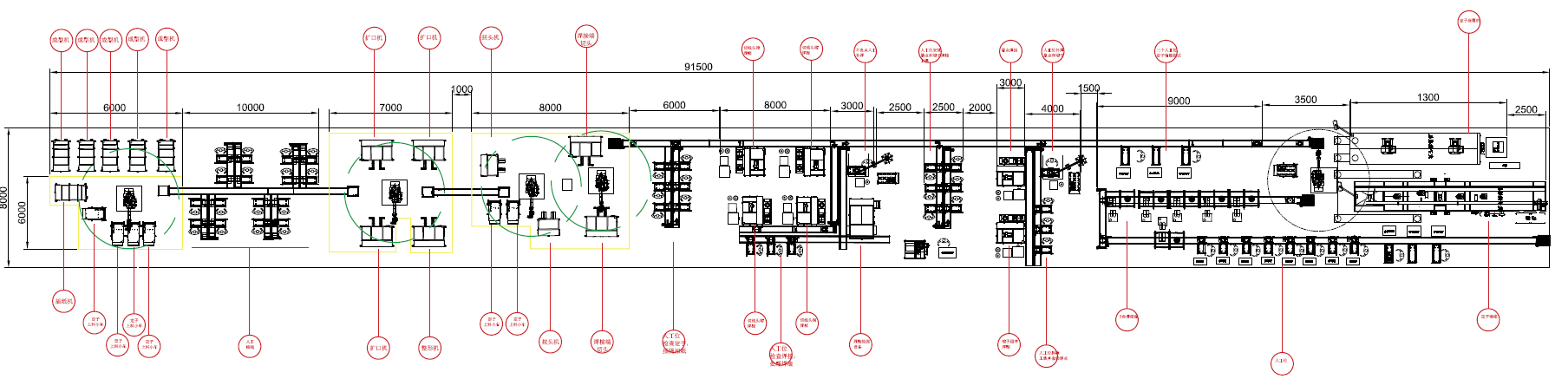

It covers special equipment for stator manufacturing of flat wire motor and automation of the whole line. It includes slot insulating paper machine, flat wire card forming machine, automatic card inserting and issuing machine, flaring machine, twisting machine, welding end cutting machine, TIG automatic welding machine and whole line automation.

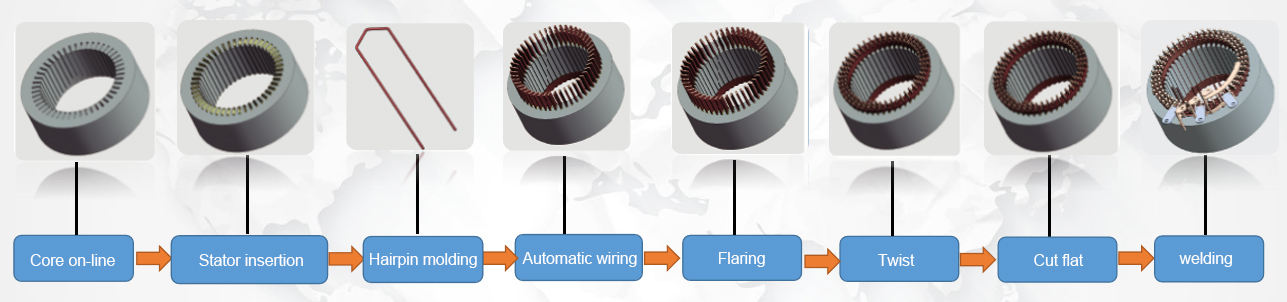

Technological Process:

Introduction to stator equipment:

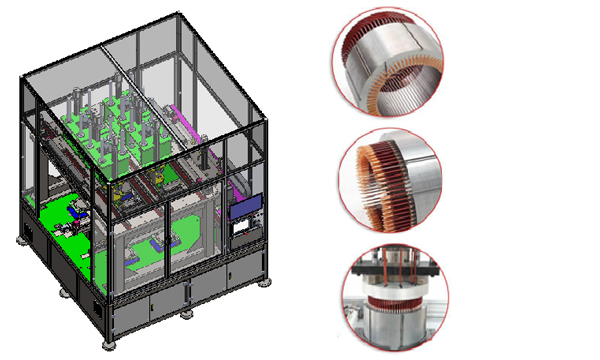

Slot insulation paper machine

Equipment introduction:

For the special equipment of driving motor stator S-shaped/B-shaped slot, the equipment is composed of body part, paper feeding part, punching part, pre-forming part, paper forming heating part, paper feeding part and servo indexing part. The servo motor is accurately indexed to ensure the accuracy and consistency of paper insertion, with high speed and high degree of automation, and can be equipped with automatic assembly line operation. The paper can be inserted for the stator of drive motor with different slot numbers and diaMeters.

U flat wire hairpin forming machine

Equipment introduction:

The equipment can realize the straightening of enamelled flat copper wire, surface paint removal, side paint removal, automatic dust removal, servo wire feeding, automatic detection, cutting, automatic splitting and forming, etc. The equipment supporting assembly line can realize fully automatic production. The equipment can process flat copper wires of different specifications and lengths; According to different needs of customers, 1KW-150KW flat wire stator can be customized and processed.

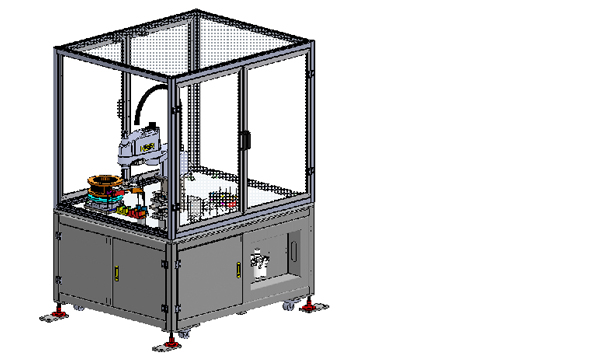

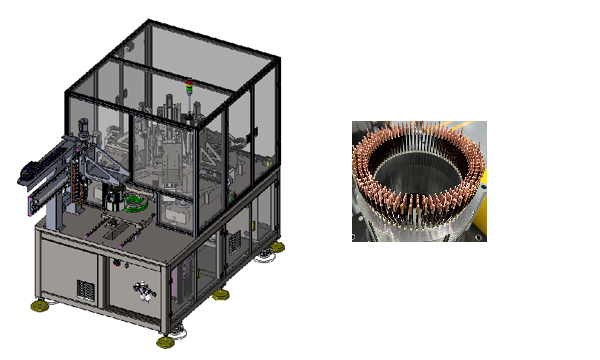

Flat wire card issuing single-pin insertion device

Equipment introduction:

The card issuing single-pin insertion device is a special device for automatic card issuing and insertion of the stator of hybrid or pure electric drive motor. It can be compatible with different linear card issuing through rapid replacement of clamping jaws by robots, and the number of flat wire layers can be compatible with 4, 6 and 8 layers.

Flat wire card issuing single-row insertion device

Equipment introduction:

The card issuing single-pin insertion device is a special device for automatic card issuing and insertion of the stator of hybrid or pure electric drive motor. It can be compatible with different linear card issuing through rapid replacement of clamping jaws by robots, and the number of flat wire layers can be compatible with 1-6 layers.

Flat wire card sending and inserting equipment in whole row

Equipment introduction:

After inserting the copper wire made by the flat wire molding machine into the stator core one by one, press the copper wire into the required size at one time through the shaping press. Manually or mechanically put the workpiece into the positioning body, the equipment will automatically send it to the working position, and automatically press down, hold and return to the position and exit.

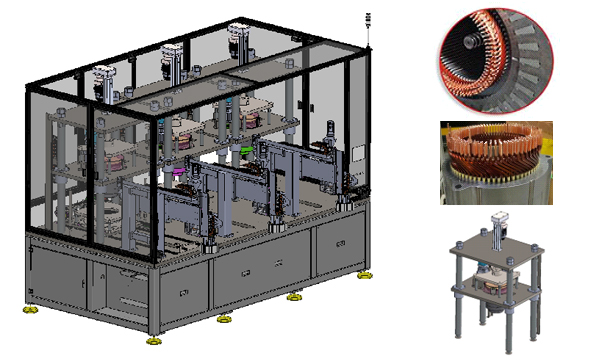

Stator flaring machine

Equipment introduction:

The flaring machine is used to expand the copper wire to a certain size after the whole copper wire is put into the slot, which is convenient for the next twisting process. The workpiece is placed on the bracket manually or mechanically - automatically fed into - 4 axis servo at the same time, flaring - rebound - cycle to the last slot - automatically push out - automatically flow to the next process.

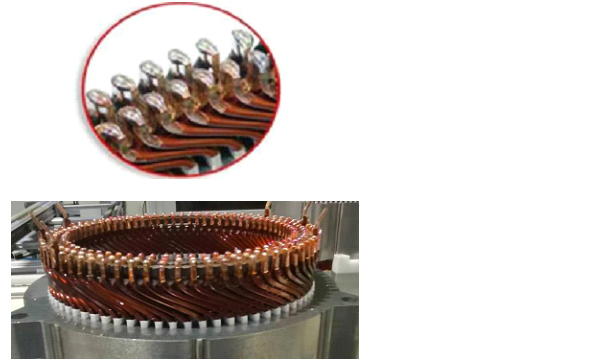

Stator twisting machine

Equipment introduction:

The twisting machine is a special equipment for twisting the stator copper wire of hybrid or pure electric drive motor. It can separate the twisting for the two, four and six layers of flat copper wire. The twisting method is servo motor twisting. The twisting angle and other paraMeters can be adjusted.

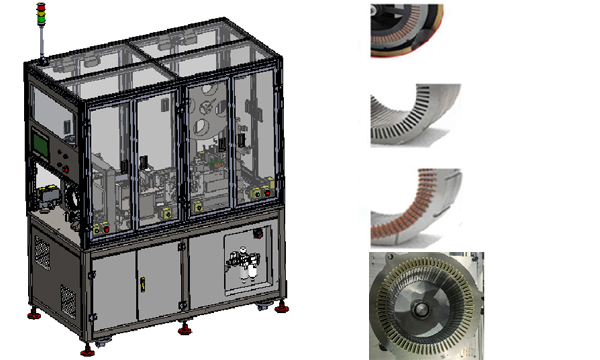

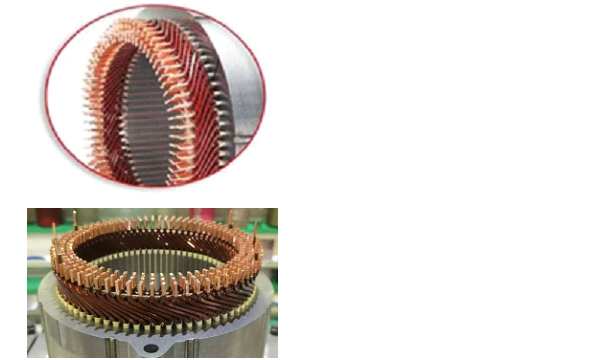

Welding end cutting machine

Equipment introduction:

The flat head machine is a process to cut the end of the stator of the torque machine flat, so as to facilitate the consistency of the next welding process and the fullness of the welding joint. The equipment is hydraulically driven. The tooling part adopts integral module for easy replacement.

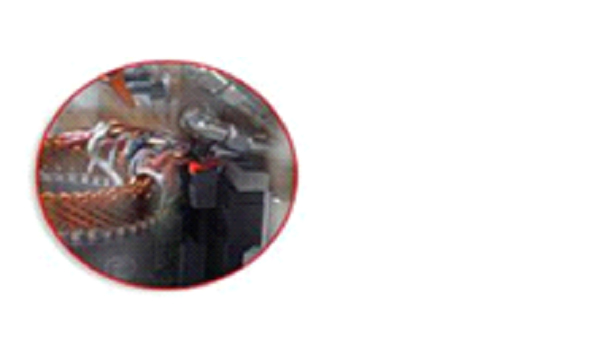

TIG automatic welding machine

Equipment introduction:

TIG welding machine is the key equipment for hybrid power and pure electric drive motor welding. The equipment adopts the argon arc welding principle to weld two or four copper wires together in two. The servo motor ensures the accuracy of each slot welding point through worm gear and worm indexing. The welding machine uses Panasonic or Vonex argon arc welding machine. The equipment can automatically complete clamping, welding, loosening, indexing and welding until the last slot stops, and the workpiece automatically ejects.

Star point and three-phase wire terminal welding machine

Equipment introduction:

Special welding equipment for stator lead-out enameled wire and terminal fusion welding;

Switchboard: 0512-62981499

Fax: 0512-62981525

E-mail: tech-shine@tech-shine.com.cn

Address: No. 938, Chengyang Road, Economic Development Zone,

Xiangcheng District, Suzhou, Jiangsu Province

Focusing