MENU

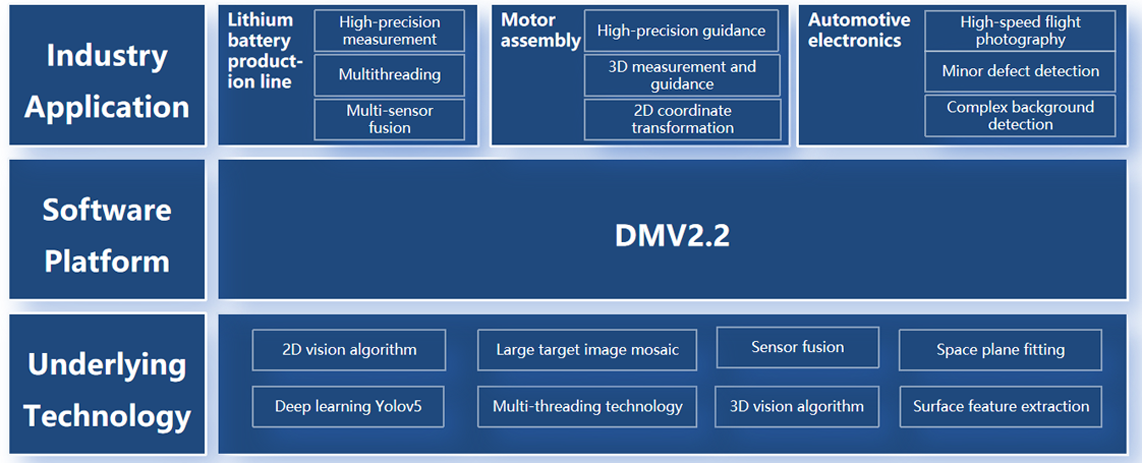

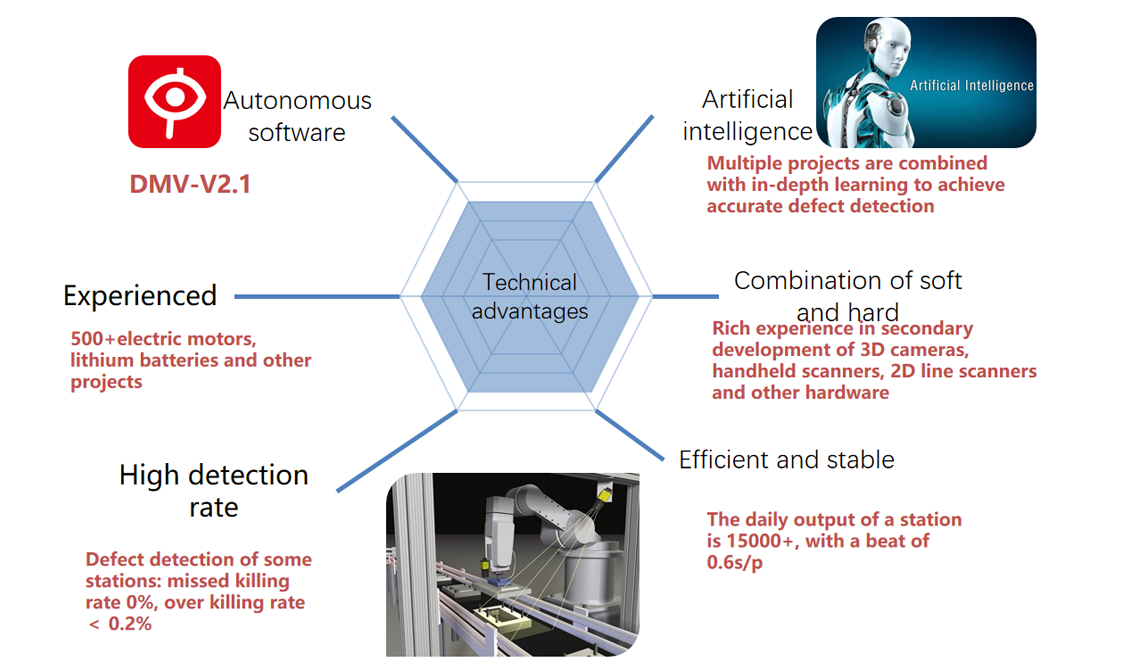

The introduction of artificial intelligence makes our defect detection system more flexible and stable.

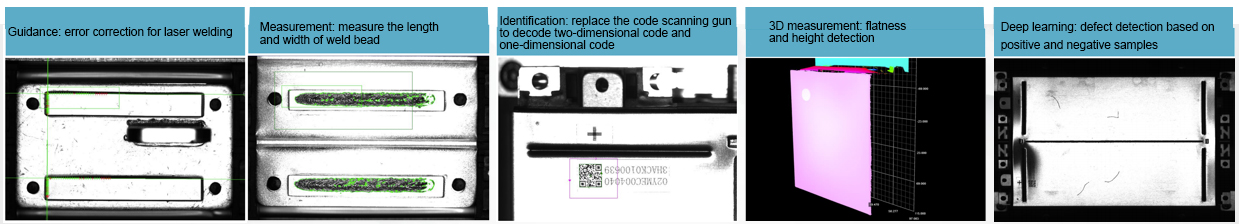

Stability: the stability of detection, measurement and other applications is up to 99%

Accuracy: good light source system design and rich calibration experience provide guarantee for accurate guidance

Convenient operation: complete software team and friendly man-machine interface

Intelligence: The model based on deep learning can effectively identify various defects

Many types of inspection: 2D size, 3D flatness, scratches and stains

Strong data fusion: all test items are directly integrated with MES

Fast customization: the test content can be customized

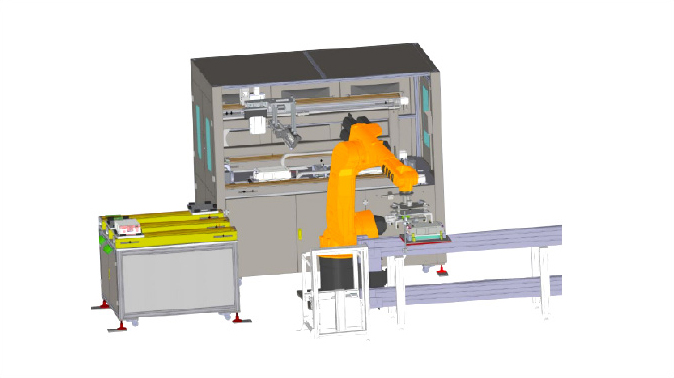

Hardware composition

2D area array camera - information collection of scratches, oil stains, plane dimensions, etc

3D laser profiler - flatness and other height related information collection

2D linear array camera - profile, friction mark and other information collection

Switchboard: 0512-62981499

Fax: 0512-62981525

E-mail: tech-shine@tech-shine.com.cn

Address: No. 938, Chengyang Road, Economic Development Zone,

Xiangcheng District, Suzhou, Jiangsu Province

Focusing