| Customer Name | XX Energy Technology Co., Ltd |

| Factory Address | Zhejiang |

| Entry Name | MEB module line |

| Battery type | Square shell |

| Meter | VDA module: 40s/piece, MEB1P10S module 60s/piece |

| Highlights of Production Line | Full-automatic production line, manual only responsible for the docking of the testing machine in the rear section |

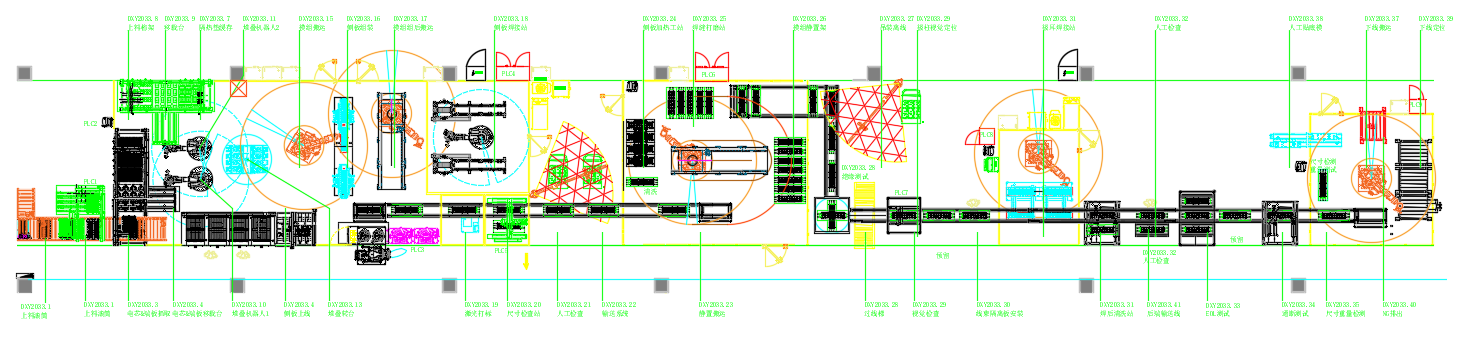

Routing:

This equipment is mainly used for automatic assembly, welding and testing of modules of lithium ion batteries. The main functions include: cell loading, OCV · test, cell side plasma cleaning, module stacking, side plate gluing, side seam welding, seam welding automatic cleaning, laser coding, module size detection, module standing, module bottom film pasting, insulation test, Busbar · pre-welding photography, harness isolation plate installation, Busbar welding, automatic weld cleaning, EOL test, module height detection, module weighing, module offline and other functions. Flexible design, through fine-tuning mechanism, changing fixture, and switching procedure, can realize fast and compatible type change of different battery modules. Integrated with powerful data management function, production information real-time interface display, product and equipment parameters local saving, uploading, MES, tracing.