2022-12-29

2022-12-29

Recently, Suzhou Municipal Bureau of Industry and Information Technology announced the list of provincial specialized new small and medium-sized enterprises (the second batch) in 2022, and our company was on the list!1、 What is "specialized and special"?"Specialization" means specialization and special technology;"Precision" means the delicacy of products, the profundity of process technology and the refinement of enterprise management;"Special" means the uniqueness and specialization of products or services;"New" means independent innovation, model innovation and novelty."Specialization, specialization and innovation" refers to the development characteristics of enterprises with specialization, refinement, specialization and novelty. Specialization, specialization and innovation are entrusted with the mission of "filling gaps" and "filling weaknesses" in the value chain and supply chain of China's manufacturing industry, and their innovation-driven characteristics play an important role in the transformation and upgrading of the manufacturing industry.2、 Understanding of "specialization and novelty"01 Specialization: Deeply cultivate the main business, and do it with perseveranceTech-Shine will continue to develop in the core business direction of high-end manufacturing, and establish a professional cooperation system with leading enterprises of new energy vehicles; At the same time, we should explore blank areas, aim at specific targets, and continue to develop business markets.02 Refinement: keep improving and carry forward the spirit of craftsmanshipTech-Shine will continue to help its main products take the path of deep research and development, forge its own brand and improve its brand influence. At the same time, we will continue to increase digital transformation to help the team improve quality and efficiency.03 Characteristic: differential positioning, trend leadingTech-Shine will use its own technical advantages and industry experience to gain insight into industry trends, make differentiated positioning, and lead product iterative development.04 Innovation: make up for weaknesses and forge strengths, and become the birthplace of innovationTech-Shine will continue to increase investment in research and development, seek the advantages of source innovation, lay out high-value patents in advance, and seek new breakthroughs in industrialization and commercial application!

2022-11-16

2022-11-16

On November 15, Suzhou Municipal Bureau of Industry and Information Technology announced the list of municipal industrial design centers to be recognized in 2022. A total of 14 enterprises in Xiangcheng District were evaluated. As the key investment attraction enterprises in Xiangcheng District in 2022, our company was listed!As an important link with the most value-added potential in the value chain of manufacturing industry, industrial design plays an important role in enhancing the added value of products, enhancing the core competitiveness of enterprises, and promoting the transformation and upgrading of industrial structure. The award of "Suzhou Municipal Industrial Design Center" is a full affirmation of Tech-Shine's ability!In the future, Tech-Shine will live up to its trust and mission, enhance confidence and forge ahead with courage, closely focus on the new energy industry, take intelligent manufacturing as the core, promote the deep integration of industrial design and manufacturing, and help the high-quality development of the national industrial economy.

2022-09-27

2022-09-27

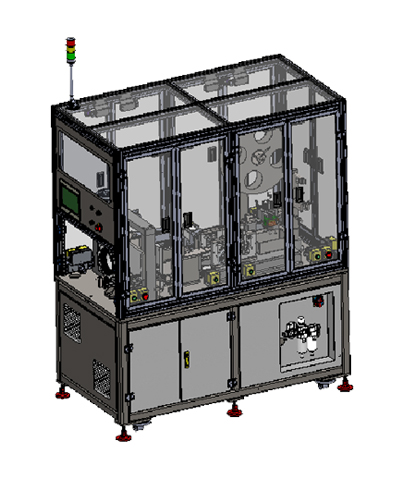

In September, Suzhou Tech-Shine lntelligent Solution Co., td (hereinafter referred to as "Tech-Shine Intelligence") will soon deliver the first wire harness assembly line for new energy vehicles. The project only took four months to complete the relevant work from design, assembly and commissioning to pre-acceptance in the factory, and fully achieved the expected technical indicators and parameters, which was highly affirmed by the user!01 Strategic layoutIn recent years, Tech-Shine Intelligence has fully demonstrated the team's high-level technical level and the execution of the whole industry chain in the fields of new energy vehicle motor drive, power lithium battery, etc. In 2021, the company added the business direction of new energy automotive electronics. The R&D team has developed the core equipment of automotive electronics such as pin insertion machine, testing machine, assembly machine, etc., which has been officially delivered to customers for mass production. At the same time, a team was formed to seek new breakthroughs in the field of new energy vehicle wiring harness.In June this year, the company cooperated with the world's top 500 enterprises to develop a new generation of harness assembly line for the global leader of new energy vehicles.02 Product OverviewThis equipment is a new type of fully automatic equipment for automatically wrapping adhesive tape, automatically labeling, automatic electrical testing, visual appearance testing, and automatic blanking of wire harness products. The automatic tape machine is used for winding, which can realize the automatic winding of any size tape in multiple positions, and strictly control the position and size tolerance; The automatic labeling module can achieve accurate labeling without wrinkles; Through automatic electrical test, CCD detection and other functions, the product qualification rate and production efficiency are greatly improved.Automobile electronic harness assemblyHigh-speed precision assembly of automobile electronicsAuto electronic high-speed pin insertion machineAutomobile electronic high-speed assembly03 Looking forward to the new journeyWe have established a solid cooperative relationship with the world's top 500 enterprises and become a pioneer in the new energy automotive electronics industry. In the future, Tech-Shine Intelligence will continue to increase its team building efforts and make every effort to provide the overall solution of the whole supply chain for the head customers of the new energy industry.

2019-11-14

2019-11-14

Recently, the National Leading Group Office for the Identification and Management of High-tech Enterprises issued the Notice on Publicizing the List of the First Batch of High-tech Enterprises to be Identified in Jiangsu Province in 2019. Among them, Suzhou Tech-Shine lntelligent Solution Co., td (hereinafter referred to as "Suzhou Tech-Shine") is prominently listed.The identification of high-tech enterprises is under the guidance, management and supervision of the Ministry of Science and Technology, the Ministry of Finance and the State Administration of Taxation. It has strict requirements for the core independent intellectual property rights, the ability to transform scientific and technological achievements, the level of research and development organization and management, and various growth indicators of enterprises. In addition to the overall business performance of enterprises, it is more important to focus on the management level of enterprise innovation and research and development, product technology content, achievement transformation ability, and growth The review process of quality assurance and other important indicators is strict and rigorous. High-tech enterprises will not only enjoy the tax reduction of relevant national preferential policies, and the enterprise income tax can be reduced from 25% to 15%, but also can obtain more scientific research funds and channels for applying for scientific research projects, which is of great significance to promote the company's scientific and technological innovation and sound development.This time, Suzhou Tech-Shine successfully passed the identification of Jiangsu Province's high-tech enterprises, marking that our company has strong technological innovation ability, high market development ability and management level. In the future, our company will continue to strengthen its technological innovation capability, improve its service quality and realize its enterprise value in high-tech services.

2019-11-13

2019-11-13

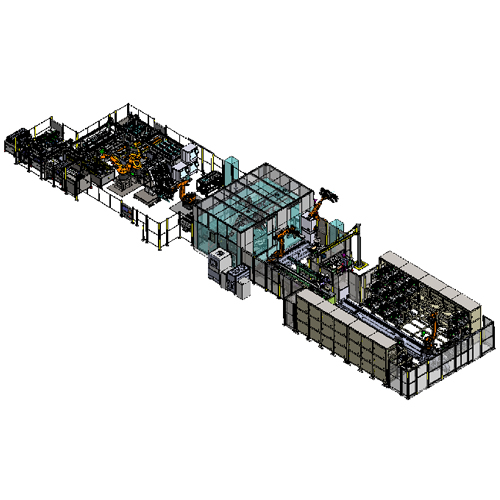

Recently, the project contracted by our company - Huizhou Yiwei Lithium Soft-packing Module Automation Production Line Project has completed installation and commissioning, and is now officially put into small batch production to achieve the perfect delivery of the project!The project is a full-automatic soft-packingModule line, which is composed of four modules: core processing module, module assembly module, large module stack module, large module assembly and welding module, and module test offline.Five six-axis robots (three large robots are responsible for handling and two small robots are responsible for laser welding), five gluing equipment (two single-component and three two-component) and five laser welding machines are used in the whole line.Floor area of the whole line: 62m × 6m; The design meter of the whole line is 12ppm.In the face of tight time, heavy tasks and short construction period, the project took only 120 days from design, production, installation, commissioning to final production through the tacit cooperation and joint efforts of the on-site staff of the customer and the team members of our company, which reflects the efficient work efficiency of Tech-Shine and perfectly demonstrates the excellent design and construction ability of Tech-Shine. Our rigorous and pragmatic work attitude and professional technical level have won the recognition of customers. This installation lays a good foundation for further cooperation between the two companies.Suzhou Tech-Shine lntelligent Solution Co., td has always adhered to the best quality and won the recognition of customers with advanced technology and excellent quality. In the future, Tech-Shine will further develop and innovate to bring high-quality products and services to customers, and is committed to the world's best "provider of integrated solutions for automated intelligent manufacturing".

2018-12-23

2018-12-23

Recently, the National Leading Group Office for the Identification and Management of High-tech Enterprises issued the Notice on Publicizing the List of the First Batch of High-tech Enterprises to be Identified in Jiangsu Province in 2019. Among them, Suzhou Tech-Shine lntelligent Solution Co., td (hereinafter referred to as "Suzhou Tech-Shine") is prominently listed. The bell of the New Year is about to ring; The wheel of time has left a deep impression. With the warm sunshine in winter; From the city of mountains and rivers and the city of Changshou, the moving news came from Pubei - "The production line of Gaomai automobile power battery in Pubei was put into operation smoothly"."Pubei Gaomai New Energy Technology Co., Ltd." is a major landmark project in the industrial transformation of Changshou Town. After completion, it can produce 50000 new energy power trucks annually, with a total investment of 3.5 billion yuan. The fully automated production line for the production of power battery packs, the core component of new energy trucks, was built by Suzhou Tech-Shine lntelligent Solution Co., td. This is also the second cooperation between Suzhou Tech-Shine and Gaomai.The production line is composed of mold assembly line+pack box assembly line. The mold assembly line is composed of the cooperation of 9 robots and the scheduling of 2 material AGVs to realize the full automatic production from the cell line to the module molding line. The PACK box assembly line uses AGV as the transportation carrier, and combines the scheduling of MES system to realize the intelligent operation of the workshop. The design meter of the whole line is 50s/moudle, and its daily production capacity can reach 150 battery packs. The project lasted only 140 days from design, production, installation, commissioning to the final production. This cooperation not only reflects the efficient work efficiency of Tech-Shine, but also perfectly demonstrates the excellent design and construction ability of Tech-Shine.On the occasion of the New Year's Day, all staff of Tech-Shine wish new and old friends a happy New Year. At the same time, Tech-Shine will forge ahead and continue to make great achievements in the coming 2019!